- Contact Person : Ms. Tian Angela

- Company Name : Ningbo Shanquan Building Material Co., Ltd.

- Tel : 86-571-87041027

- Fax : 86-571-87041021

- Address : Zhejiang,YuYao,Qinggang Industrial Zone, Moushan Town

- Country/Region : China

- Zip : 315458

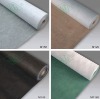

breathable foil / breathable membrane / roof underlay

waterproof breathable roof felt / water resistant / vapour permeable/ slopping roof tile underlay / breathable housewrap felt

Breathable Membrane is a water-resistant material which will allow water vapour to pass through when there is a difference in humidity on opposite sides of it.

Breathable membranes are used on the outside of frame walls under the exterior finish material. They have three functions to perform:

to shed moisture and restrict any rain water which penetrates past the exterior finish from reaching the wood wall,to perform as a breather material allowing any moisture within the wall cavity to escape by diffusion through the membrane to the exterior, andto act as a wind barrier to restrict movement of air through the wall.To qualify for the above functions the breather membrane must have good "water resistance", good "water vapour permeability", and good "air barrier properties".

Breathabe Membrane Specification

1, Standard : EN13859-1 (CE mark optional)2, Weight: 80g, 90g, 100g, 115g, 120g, 135g, 140g, 160g, 180g/m2.3, water resistance: calss W1 (water column ≥1500mm)4, breathability: ≥2250g/m2/24h (SD-value 0.02m)5, UV resistance: ≥3 months 6, Roll width: 1.5m 7, Roll length: 50m 8, Packing: each roll with PE bag or PVC shrink wrap film.9, Loading: with pallets packing or bulk loading.Key Features of Breathable Membrane:

CE certificated, high quality with competitive priceWaterproof & vapor permeableHigh breathability3-layer laminate (PP+PE+PP)Anti-UV stable; anti-aging stableExcellent tensile and nail tear strength Good flexibility and ductilityLight weight and thin, slip-resistant surfaceSimple handling and easy to useEnergy savingLong term durabilityUse as roofing underlayment or housewrapTechnical data | Testing Standard | Unit | Specifications | |||||

M90 | M100 | M120 | M140 | MF140 | MF160 | |||

Weight per unit area | EN1849 | G/M2 | 90±10% | 100±10% | 120±10% | 140±10% | 140±10% | 160±10% |

Width | EN1848 | M | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

Resistance to Water penetration | EN1928-2000 | W1 | W1 | W1 | W1 | W1 | W1 | |

Water vapour transmission | EN1931 | G/M2.24h | 2250 | 2250 | 2250 | 2250 | 2250 | 2250 |

Tensile strength(CD) | EN12311-1 | N/50MM | 75±15% | 100±15% | 120±15% | 150±15% | 150±15% | 170±15% |

Tensile strength(MD) | EN12311-1 | N/50MM | 115±15% | 150±15% | 180±15% | 200±15% | 200±15% | 230±15% |

Nail tearing strength(CD) | EN12310-1 | N | 45±15% | 60±15% | 80±15% | 90±15% | 80±15% | 90±15% |

Nail tearing strength(MD) | EN12310-1 | N | 55±15% | 70±15% | 90±15% | 100±15% | 90±15% | 100±15% |

Reaction to fire | EN13501-1:2002 EN11925-2 | E | E | |||||

UV resistance | EN13859-1 | Month | 3 | 3 | 3 | 3 | 3 | 3 |

Properties alternation after artificial aging | ||||||||

Tensile strength MD/CD | En13859-1 | % | -30%/-30% | -30%/-30% | -30%/-30% | -30%/-30% | -30%/-30% | -30%/-30% |

penetration | EN13859-1 | W1 | W1 | W1 | W1 | W1 | W1 | |

breathable foil / breathable membrane / roof underlay